Quality

Waterjet Newsletter – 06/13/2006

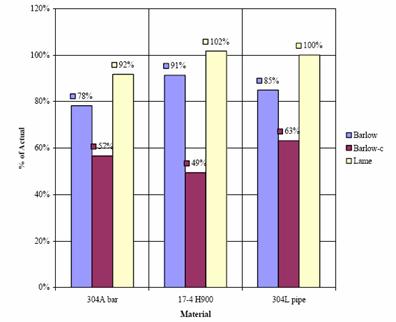

Pressure Limits of Tapered Pipe Thread Connections An experimental study was conducted

by Wright et al* to determine the maximum allowable pressures for tapered

pipe thread connections used in the waterblast

industry. Its main points are reviewed here. The two popular equations for

calculating burst pressure of a cylinder are as follows: Barlow equation for thin walled

cylinders (ID/wall > 10)

Lame’ equation for thick walled

cylinders (ID/wall < 10)

Where P = burst pressure, S =

tensile strength of material, t = wall thickness, D = outer diameter, w =

wall ratio (OD/ID). All the test

samples in this study had a wall ratio less than 10. Using a safety factor of

2.5, specified by Waterjet Technology Association, the maximum allowable

operating pressure can be calculated with P/2.5. Tests were done to verify these two

equations applied to tapered pipe thread connections. Test samples (including

6 solid plugs, 24 male pipes, 16 pipe couplings) were made from 303, 304A

bar, 304L seamless schedule 160 pipe and 17-4 H900

stainless steel. Tests with different thread engagement and multiple

assemblies were also done. A single stroke intensifier pump (80 kpsi maximum operating pressure) was used for most of the

tests. In some cases leakage of test fitting exceeded the capacity of the

intensifier pump and then a triplex plunger pump (40 kpsi

maximum) was used instead.

Reported test results include

failure pressure and failure mode of each test, photos of tested samples

showing the failure modes, as well as comparison with calculated values. To

the left is a graph that illustrated the ratio of calculated values to actual

failure pressures. It appears that Lame’ equation most accurately predicts

the failure pressure. *Wright, D., Wolgamott, J., and

Zink, G. (2003) Pipe threads --- what is the limit? Proceedings of the 2003

WJTA American Waterjet Conference, Beyong High Pressure ·

Courtesy to Prof. O.V. Krishnaiah

Chetty, an electronic copy of his paper “Studies

on Recharging of Abrasives in Abrasive Water Jet Machining” is now available

at http://www.qualjet.com/Newsletter/RechargingAbrabsive.pdf.

Professor Chetty can be reach at ovk@iitm.ac.in. |

|

QualJet

LLC

Quality Waterjet Spare Parts Specialist · Quality

Waterjet Spare Parts o Meets/exceeds

OEM standards o 30%

longer operation life time than competing products · Extensive

Parts Coverage for: o Flow

style, IR Style o 40K/55K

pumps o Intensifiers

o On/off

valves o Cutting

head o Swivels · OEM

Expert o 20+

year waterjet OEM experience (via OH Precision) o Accept

small OEM order Durable, Compact 40K

PSI Pumps

· Long

operation lifetime · Highly

cost-effective · Light

weight and compact · Contact

us for o

Custom power end o

50K psi models o

Private labeling o

Custom design QualJet LLC

1-866-QUALJET (782-5538) Fax: 425-378-7776 Email: info@qualjet.com Website: www.qualjet.com To unsubscribe the

newsletter: unsubscribe@qualjet.com For newsletter archive: www.qualjet.com/Newsletter.htm

Copyright ©2005, QualJet LLC |

|

|