Quality

Waterjet Newsletter – 05/30/2006

Recycling Abrasive for AWJ Cutting A question that was frequently

asked is whether the abrasive used in AWJ (abrasive waterjet) cutting can be recycled. If recycling is to be performed, how much new abrasive

should be added to regain the cutting efficiency? Babu

and Chetty published a paper* based on their

experimental studies of this subject and here are the highlights. Their experiments were done with

an abrasive waterjet cutting system, running at 225 MPa

(32.6 kpsi). Sample material for the cutting tests

was aluminum. Two types of

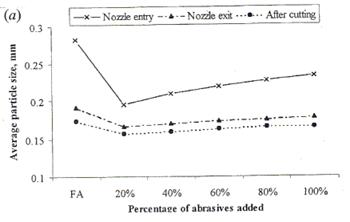

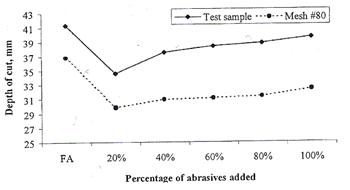

Cutting performances are affected

by abrasive particle sizes. Depth of cut was reduced as a result of abrasive

particle disintegration. Adding fresh abrasive can regain some of it. The graph to the left showed that a 40% fresh- abrasive

addition is most effective. This graph also showed that the specially

formulated garnet had 12 to 24% advantage over * Babu, M. Kantha

& Chetty, O. V. Krishnaiah

(2002). Studies on recharging of abrasives in abrasive water jet machining.

International Journal of Advanced Manufacturing Technology, 19, 697-703. |

|

QualJet

LLC

Quality Waterjet Spare Parts Specialist · Quality

Waterjet Spare Parts o Meets/exceeds

OEM standards o 30%

longer operation life time than competing products · Extensive

Parts Coverage for: o Flow

style, IR Style o 40K/55K

pumps o Intensifiers

o On/off

valves o Cutting

head o Swivels · OEM

Expert o 20+

year waterjet OEM experience (via OH Precision) o Accept

small OEM order Durable, Compact 40K

PSI Pumps

· Long

operation lifetime · Highly

cost-effective · Light

weight and compact · Contact

us for o

Custom power end o

50K psi models o

Private labeling o

Custom design QualJet LLC

1-866-QUALJET (782-5538) Fax: 425-378-7776 Email: info@qualjet.com Website: www.qualjet.com To unsubscribe the

newsletter: unsubscribe@qualjet.com For newsletter archive: www.qualjet.com/Newsletter.htm

Copyright ©2005, QualJet LLC |

|

|