Quality

Waterjet Newsletter – 03/11/2008

Forming

and Welding Using a High Speed Liquid Impact Liquid impact on a target has a

similar effect to the well documented explosive forming and welding. Samardzic et al.* presented an experimental study to

prove that.

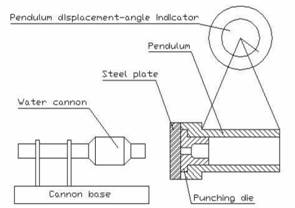

Their experimental setup was illustrated in the diagram.

The target was mounted on a ballistic pendulum to allow impact momentum

measurement. In the forming experiments the target was backed by a die while

in the welding experiments, the samples to be welded were held by a special

holder.

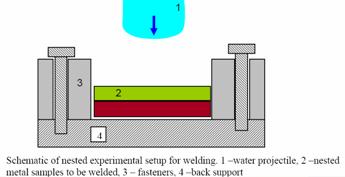

In the welding experiments, the samples were held by the

special holder as shown. The combinations of metal samples include:

Copper-Nickel-Copper, Brass-Nickel-Brass, Copper-Copper, and Copper-Steel.

The projectile speed used for welding experiments was in the range of 750-850

m/s because it was found this lower range of speed produced a stronger joint.

It was also found that separation of the sample parts provided a better

condition for welding. Ultrasonic technique was used to examine the welded

interface. Out of the 20 experiments only one was not successful. The welding

mechanism was attributed to the superposition and propagation of the

compression and rarefaction waves generated by the impact which causes

melting of the interface. * Samardzic et al. (2007) “Investigation of Metal

Processing Using a High Speed Liquid Impact”, Proceedings of 2007 American

WJTA Conference and Expo, August 19-21, |

|

QualJet LLC

Quality Waterjet Spare Parts Specialist · Quality

Waterjet Spare Parts o Meets/exceeds

OEM standards o 30%

longer operation life time than competing products · Extensive

Parts Coverage for: o Flow

style, IR Style o 40K/55K

pumps o Intensifiers

o On/off

valves o Cutting

head o Swivels · OEM

Expert o 20+

year waterjet OEM experience (via OH Precision) o Accept

small OEM order Durable, Compact 40K

PSI Pumps

· Long

operation lifetime · Highly

cost-effective · Light

weight and compact · Contact

us for o

Custom power end o

50K psi models o

Private labeling o

Custom design QualJet LLC

1-866-QUALJET (782-5538) Fax: 425-378-7776 Email: info@qualjet.com Website: www.qualjet.com To unsubscribe the

newsletter: unsubscribe@qualjet.com For newsletter archive: www.qualjet.com/Newsletter.htm

Copyright ©2005, QualJet LLC |

|

|