Quality

Waterjet Newsletter – 10/16/2007

Dental Waterjets Parameters Dental drill is currently the most popular tool for

removing tooth decay. Even though the drill is fast and inexpensive, it may

cause pain and dentin micro fracture. The drill tip is often too large and

removes unnecessarily healthy enamel as a result. An alternative way since

1995 is the use of laser. But the equipment cost of laser is relatively high

and it also takes longer time than the drill. Another alternative method is

air abrasion (sand-blasting). But it is also relatively slow and has an issue

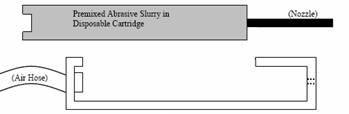

with dust control. Grygla & Todd* anticipated

that a low pressure abrasive water jet should have the potential to overcome

the weaknesses of these methods.

The first method is a xanthan polymer suspension.

After the xanthan

suspension was prepared and tested at several different concentrations

levels, it was determined that a xanthan

concentration of 0.50% provides sufficient viscosity to suspend the aluminum

oxide particles. However, the xanthan suspension

would leave a layer of obscure slurry, which could block the dentist's vision

of the tooth. The second method is a magnetic stirring apparatus. A ferrous

rod was placed inside of a 50 ml container that contains a mixture of water

and 11.0% abrasive material by weight. The container was then placed on a

magnetic stirring table that has a rotating magnetic bar. The rod inside the

container responded to the rotating action of the magnetic bar and was able

to successfully mix the water and abrasive to create the desired homogeneous

slurry. The third method is by ultrasonic cavitation.

A sonic dismembrator,

model 550 by Fisher Scientific was used to produce the ultrasonic cavitation. The sonicating horn

was lowered into a 50 ml container filled with the abrasive material. By

testing at several different intensity levels (0-5), complete mixing was

achieved at a setting of three. It was also noted that ultrasonic cavitation produced an extreme amount of heat, causing

temperature rise at 1.2°C/min. These test results serve as stepping stones

for future research. *Grygla, M.S. & Todd, R.H. (2007) An investigation of methods to

homogeneously entrain and suspend abrasive particles in a low pressure dental

water jet, in Proceedings of the 2007 American WJTA Conference and Expo,

August 19-21, Houston, Texas, Paper 4-D. |

|

QualJet LLC

Quality Waterjet Spare Parts Specialist · Quality

Waterjet Spare Parts o Meets/exceeds

OEM standards o 30%

longer operation life time than competing products · Extensive

Parts Coverage for: o Flow

style, IR Style o 40K/55K

pumps o Intensifiers

o On/off

valves o Cutting

head o Swivels · OEM

Expert o 20+

year waterjet OEM experience (via OH Precision) o Accept

small OEM order Durable, Compact 40K

PSI Pumps

· Long

operation lifetime · Highly

cost-effective · Light

weight and compact · Contact

us for o

Custom power end o

50K psi models o

Private labeling o

Custom design QualJet LLC

1-866-QUALJET (782-5538) Fax: 425-378-7776 Email: info@qualjet.com Website: www.qualjet.com To unsubscribe the

newsletter: unsubscribe@qualjet.com For newsletter archive: www.qualjet.com/Newsletter.htm

Copyright ©2005, QualJet LLC |

|

|