Quality

Waterjet Newsletter ¨C 09/12/2006

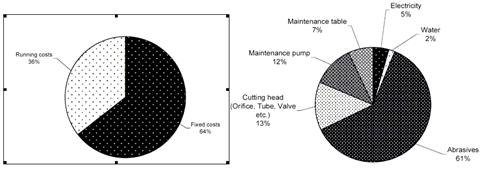

Cost Analysis of AWJ Cutting Cost analysis of abrasive water

jet (AWJ) cutting is an important but complicated task. Several attempts have

been made. The latest attempt was from Andersson and Holmqvist(*). The results

of their analysis are highlighted here. Their cost analysis is part of a

joint effort from a group of 12 members including equipment developers and

users, aimed to promote competitive use of waterjet technology. The primary

goal is to provide practical guides for optimizing the process. A database

containing 500 different combinations of process parameters are being built.

The optimum setting is then determined. As an example, the following

charts (Left ¨C total cost; Right ¨C running cost) shows the cost distributions

based on these assumptions: investment 272,000 €, abrasive 0.43 €/kg,

operator 32.6 €/h, working hours per year 3750 h, pump power 37 kW, max pump

pressure 410 MPa, utilization 70%, orifice/focusing tube 0.35/1.1 mm,

abrasive feeding 625 g/min, 1 cutting head, cutting speed 88 mm/min (cutting

18 mm stainless steel).

Cost distribution charts (in the

paper) for 2 cutting heads as well as 4 cutting heads with smaller nozzles

(0.25/0.76 mm) clearly indicate the advantage of multiple heads in reducing

the percentage of fixed costs (from about 2/3 to about half of total costs)

and thus the cost per unit length. But that comes with more programming and

setup time, more scrap material, and reduced flexibility. Abrasive cost is the biggest part

of the running cost. Increasing abrasive feeding will increase cutting speed

up to a certain point, beyond that the trend will be flatten and even

reversed, called saturation curve. The saturation curve depends on a specific

machine setup. Higher pressure will increase the cutting speed, but will also

increase downtime and maintenance cost. As an example, pressure increase from

350 to 410 MPa will increase cutting speed by 27%, but will triple the cost

of spare parts. * Andersson,

U. and Holmqvist, G. (2005) Strategies for cost ¨C and time-effective use of

abrasive waterjet cutting, in Mohamed Hashish (Ed.), Proceedings of the 2005

WJTA American Waterjet Conference, Houston, Texas, USA, August 21-23, Paper

7B-2. Beyond High

Pressure Fredrick Equipment, a

recognized distributor of high pressure piping components, is proud to offer

QualJet/OHPˇŻs line of waterjet pumps and OEM replacement parts along with

sapphire and diamond orifice replacements, tools, gauges, and accessories.

Call toll-free at 1-888-928-3758. |

|

QualJet LLC

Quality Waterjet Spare Parts Specialist ˇ¤ Quality

Waterjet Spare Parts o Meets/exceeds

OEM standards o 30%

longer operation life time than competing products ˇ¤ Extensive

Parts Coverage for: o Flow

style, IR Style o 40K/55K

pumps o Intensifiers

o On/off

valves o Cutting

head o Swivels ˇ¤ OEM

Expert o 20+

year waterjet OEM experience (via OH Precision) o Accept

small OEM order Durable, Compact 40K

PSI Pumps

ˇ¤ Long

operation lifetime ˇ¤ Highly

cost-effective ˇ¤ Light

weight and compact ˇ¤ Contact

us for o

Custom power end o

50K psi models o

Private labeling o

Custom design QualJet LLC

1-866-QUALJET (782-5538) Fax: 425-378-7776 Email: info@qualjet.com Website: www.qualjet.com To unsubscribe the newsletter:

unsubscribe@qualjet.com For newsletter archive: www.qualjet.com/Newsletter.htm

Copyright ©2005, QualJet LLC |

|

|