Quality

Waterjet Newsletter – 08/29/2006

Waterjetting Effects on Concrete Moisture

Level This was a subject of controversy

in the cleaning and surface preparation industry. Last year Todd A. Shawver

conducted a series of tests and published a paper* to provide a scientific

answer that clears up the previous speculation. Here are the main points of

his paper. The effectiveness of water jetting

for surface preparation has been proven. Its percentage of surface

interference failure is only 7%, compared to 38% for abrasive blasting, and

31% for jack hammering. Water jetting is capable of removing invisible

contaminants, one of the main causes of coatings failures. It also eliminates

dust and does not disrupt other nearby work. Among current practices for concrete

coating removal, one of the most common methods is shot blasting with

recyclable steel shots. Some of these steel shots can escape the vacuum

system and become a potential source of coating failures. Failure to

completely remove invisible contaminants and creating dust are also the

disadvantages of shot blasting. However, with water jetting, there

has been a concern that it may increase the moisture level in the concrete

and thus cause blistering, delaminating and other forms of coating failures.

To provide a scientific answer to this question, a series of tests were done

in a controlled condition. The tests were done on smooth and clean concrete

surfaces. The target environmental condition was a sunny day with 75°F and 50% relative humidity. The

actual condition was 77°F and 55% relative

humidity as well as a light to variable wind at 3 miles per hour. The

moisture level of the concrete surface was measured with a specialized tool,

which measures the electric impedance of the concrete. The subject concrete

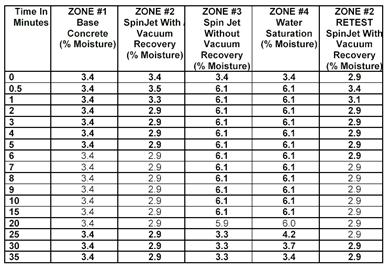

surface was divided into 4 different zones. Zone 1 was base concrete, used as

a reference. Its moisture was measured and the value was 3.4% throughout the

test duration. Zone 2 was prepared with a “SpinJet”

at 40 kpsi and 6 gpm

within a time frame of 7 seconds. A vacuum recovery system was employed to

remove the waste water. The moisture level was increased from 3.4% to 4.5%

immediately after cleaning, but then drop to 2.9% after just 2 minutes. The

reason why afterwards moisture value was lower (2.9% compared to 3.4%) was

because the reading prior to cleaning was affected by some “Iron” deposits.

The same test was repeated on the cleaned surface and the result confirmed

this (same 2.9% prior to and 2 minutes after cleaning). Zone 3 was similar to

Zone 2 but without vacuum recovery. The moisture level dropped back down to

3.3% after 25 minutes. Zone 4 was soaked with running water for a 3 hour

period to simulate saturation from precipitation. The moisture level returned

to 3.4% after 35 minutes. The table below shows the moisture variation in the

tested period.

The conclusion was that water

jetting at 6 gpm and 40 kpsi

with a vacuum recovery system does not cause any measurable increase in

moisture level of concrete surfaces. * Shawyer, Todd. A. (2005) The effects of UHP surface

preparation on concrete moisture levels using UHP water jets, in Mohamed

Hashish (Ed.), Proceedings of the

2005 WJTA American Waterjet Conference, Houston, Texas, USA, August 21-23, Paper

5B-4. |

|

QualJet

LLC

Quality Waterjet Spare Parts Specialist · Quality

Waterjet Spare Parts o Meets/exceeds

OEM standards o 30%

longer operation life time than competing products · Extensive

Parts Coverage for: o Flow

style, IR Style o 40K/55K

pumps o Intensifiers

o On/off

valves o Cutting

head o Swivels · OEM

Expert o 20+

year waterjet OEM experience (via OH Precision) o Accept

small OEM order Durable, Compact 40K

PSI Pumps

· Long

operation lifetime · Highly

cost-effective · Light

weight and compact · Contact

us for o

Custom power end o

50K psi models o

Private labeling o

Custom design QualJet LLC

1-866-QUALJET (782-5538) Fax: 425-378-7776 Email: info@qualjet.com Website: www.qualjet.com To unsubscribe the

newsletter: unsubscribe@qualjet.com For newsletter archive: www.qualjet.com/Newsletter.htm

Copyright ©2005, QualJet LLC |

|

|