Quality

Waterjet Newsletter – 7/5/2005

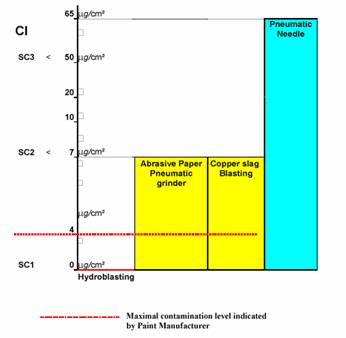

Review On Surface Preparation with Waterjets --- Part Two There are several

traditional ways of doing surface preparation. As the new kid on the block,

waterjetting is a technology that needs to be proven to be effective in this

industry. People want to know its advantages, as well as its limitations.

Trotter wrote a paper* summarizing the study he and his colleagues did to

compare hydroblasting with the other technologies. The following review will

highlight their findings. A Pulp Mill in

Although hydroblasting

was proven to be the most effective technology, the surface after hydroblasting

showed flash rust within a few hours. Therefore the surface should be painted

within two hours of hydroblasting. * Trotter, E. L. E. O., “Comparison of

surface preparation using different methods,” Proceedings of the 11th

American Waterjet Conference, Minneapolis, Minnesota, August 18-21, 2001,

Paper 57. |

|

QualJet

LLC

Quality Waterjet Spare Parts Specialist · Quality

Waterjet Spare Parts o Meets/exceeds

OEM standards o 30%

longer operation life time than competing products · Extensive

Parts Coverage for: o Flow

style, IR Style o 40K/55K

pumps o Intensifiers

o On/off

valves o Cutting

head o Swivels · OEM

Expert o 20+

year waterjet OEM experience (via OH Precision) o Accept

small OEM order Q2 Promotion

· 20%

discount for any in-stock inventory ·

Contact info@qualjet.com for details. QualJet LLC

1-866-QUALJET (782-5538) Fax: 425-378-7776 Email: info@qualjet.com Website: www.qualjet.com To unsubscribe the

newsletter: unsubscribe@qualjet.com For newsletter archive: www.qualjet.com/Newsletter.htm

Waterjets or parts for sale: Industry

jobs: qualjet.com/IndustryJobs.htm Copyright ©2005, QualJet LLC |

|

|