Quality

Waterjet Newsletter – 05/16/2006

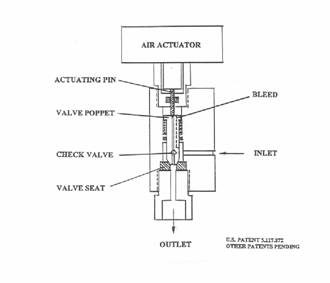

Piloted High Pressure Valves High-pressure valves are important

components in waterjetting systems. A piloted valve

design was described by Yie* and will be reviewed

here. Existing high-pressure valves have

some issues that need improvements. Because of the large force required to

open/close the valves in high-pressure applications, bulky air actuators are

usually needed. The large force involved in opening/closing of the valve

often leads to fatigue problems of valve components. Other issues include low

flow capability and leakage.

The benefits achieved by this valve design were summarized

by Yie as follows:

* Yie, G. G. (2001) THE

DEVELOPMENT OF IMPROVED HIGH PRESSURE VALVES, Proceedings of the 2001 WJTA

American Waterjet Conference, Minneapolis, Minnesota, August 18-21, Paper 59. |

|

QualJet

LLC

Quality Waterjet Spare Parts Specialist · Quality

Waterjet Spare Parts o Meets/exceeds

OEM standards o 30%

longer operation life time than competing products · Extensive

Parts Coverage for: o Flow

style, IR Style o 40K/55K

pumps o Intensifiers

o On/off

valves o Cutting

head o Swivels · OEM

Expert o 20+

year waterjet OEM experience (via OH Precision) o Accept

small OEM order Durable, Compact 40K

PSI Pumps

· Long

operation lifetime · Highly

cost-effective · Light

weight and compact · Contact

us for o

Custom power end o

50K psi models o

Private labeling o

Custom design QualJet LLC

1-866-QUALJET (782-5538) Fax: 425-378-7776 Email: info@qualjet.com Website: www.qualjet.com To unsubscribe the

newsletter: unsubscribe@qualjet.com For newsletter archive: www.qualjet.com/Newsletter.htm

Copyright ©2005, QualJet LLC |

|

|