|

Quality

Waterjet Newsletter – 04/10/2007

Monitoring AWJ Cutting Using Infrared Thermography

Kovacevic et al.* found that

infrared thermography is a very promising technique

for monitoring abrasive waterjet cutting of opaque materials and nozzle wear.

Here are the highlights of their findings.

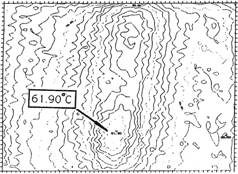

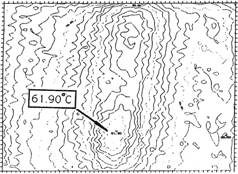

A visualization study

of abrasive waterjet cutting was previously done by Hashish, using a

high-speed camera and transparent sample materials such as Lexan. In this study, the high-speed camera was replaced

by an infrared camera, and Lexan was replaced with

blocks of aluminum and titanium alloys. One face of the sample blocks was

coated with black enamel with a known emissivity of

0.99 and was exposed to the infrared camera. The cuts were made parallel to

this exposure face with a set distance. A smaller distance has a higher

sensitivity. An increase in cutting pressure causes an increase in workpiece temperature and thus can be detected by the infrared

camera. But change in cutting speed has a minimal effect on temperature

change and thus cannot be easily picked up by the infrared camera. Titanium,

being a poor conductor, has a “sharper” infrared image than aluminum, but

requires a smaller distance to the exposure face. The figure above is an

infrared image of the jet cutting a titanium sample (from left to right). It

shows the inclination of the jet as well as two hot spots on upper and lower

portions of the jet trajectory. The data gained from the infrared images

closely match those from measurements using thermocouples. A visualization study

of abrasive waterjet cutting was previously done by Hashish, using a

high-speed camera and transparent sample materials such as Lexan. In this study, the high-speed camera was replaced

by an infrared camera, and Lexan was replaced with

blocks of aluminum and titanium alloys. One face of the sample blocks was

coated with black enamel with a known emissivity of

0.99 and was exposed to the infrared camera. The cuts were made parallel to

this exposure face with a set distance. A smaller distance has a higher

sensitivity. An increase in cutting pressure causes an increase in workpiece temperature and thus can be detected by the infrared

camera. But change in cutting speed has a minimal effect on temperature

change and thus cannot be easily picked up by the infrared camera. Titanium,

being a poor conductor, has a “sharper” infrared image than aluminum, but

requires a smaller distance to the exposure face. The figure above is an

infrared image of the jet cutting a titanium sample (from left to right). It

shows the inclination of the jet as well as two hot spots on upper and lower

portions of the jet trajectory. The data gained from the infrared images

closely match those from measurements using thermocouples.

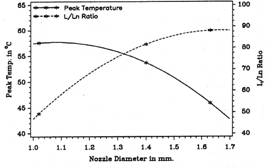

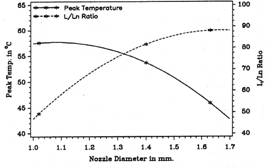

The same infrared

camera was also used to monitor the wear of AWJ nozzle. The plot on the right

shows that, as the nozzle diameter increased, the peak temperature decreased

and the location of the peak temperature (indicated by the L/Ln ratio) migrated from top to bottom, indicating the downward

progress of wear pattern. The same infrared

camera was also used to monitor the wear of AWJ nozzle. The plot on the right

shows that, as the nozzle diameter increased, the peak temperature decreased

and the location of the peak temperature (indicated by the L/Ln ratio) migrated from top to bottom, indicating the downward

progress of wear pattern.

* Kovacevic, R.,

Mohan, R., & Beardsley, H.E. (1996) Monitoring of thermal energy

distribution in abrasive waterjet cutting using infrared thermography,

Journal of Manufacturing Science and Engineering, November, Vol. 118,

pp555-563.

Beyond High

Pressure

- Fredrick Equipment, a recognized

distributor of high pressure piping components, is proud to offer

QualJet/OHP’s line of waterjet pumps and OEM

replacement parts along with sapphire and diamond orifice replacements,

tools, gauges, and accessories. Call toll-free at 1-888-928-3758.

|

|

QualJet

LLC

Quality Waterjet

Spare Parts Specialist

· Quality

Waterjet Spare Parts

o Meets/exceeds

OEM standards

o 30%

longer operation life time than competing products

· Extensive

Parts Coverage for:

o Flow

style, IR Style

o 40K/55K

pumps

o Intensifiers

o On/off

valves

o Cutting

head

o Swivels

· OEM

Expert

o 20+

year waterjet OEM experience (via OH Precision)

o Accept

small OEM order

Durable, Compact 40K

PSI Pumps

· Long

operation lifetime

· Highly

cost-effective

· Light

weight and compact

· Contact

us for

o

Custom power end

o

50K psi models

o

Private labeling

o

Custom design

QualJet LLC

12819 SE 38th Street, #240

Bellevue, WA

98006

1-866-QUALJET (782-5538)

Fax: 425-378-7776

Email: info@qualjet.com

Website: www.qualjet.com

To unsubscribe the

newsletter: unsubscribe@qualjet.com

For newsletter archive:

www.qualjet.com/Newsletter.htm

Copyright ©2005, QualJet LLC

|